Conversion

Technology

Plastipak Excels in Innovative Conversion Technology

We provide advanced solutions for transforming raw materials into high-quality packaging products. With a commitment to sustainability, Plastipak leverages cutting-edge conversion techniques to create eco-friendly packaging options that meet the evolving needs of industries worldwide.

Wide Range of Offerings

PET

(Polyethylene terephthalate)

- Injection Molding

- Single Stage ISBM

- Two Stage ISBM

- ePET

- Wide Mouth

- Lightweight Neck Finishes

- Blow Trim

- Multilayer

- Barrier

HDPE

(High density polyethylene)

- Wide Mouth

- Extrusion Molding

- Non-Round

- Multilayer

- Barrier

PP

(Polypropylene)

- Injection Molding

- Wide Mouth

- Injection Blow Molding

- Retort Packaging

- Blow Trim

- Multilayer

- Barrier

LDPE

(Low density polyethylene)

- Injection Blow Molding

Our Proprietary Technologies

PET

High-output manufacturing of customizable PET packaging. Lightweight, recyclable PET packaging is ideal for a variety of applications.

Key Benefits

• Global leader in blow molding

• Single Stage ISBM

• Two Stage ISBM

• Full range of narrow neck & wide mouth options

• Lightweight neck finishes

• Injection Molding

• Blow Trim

• Multilayer

• Barrier

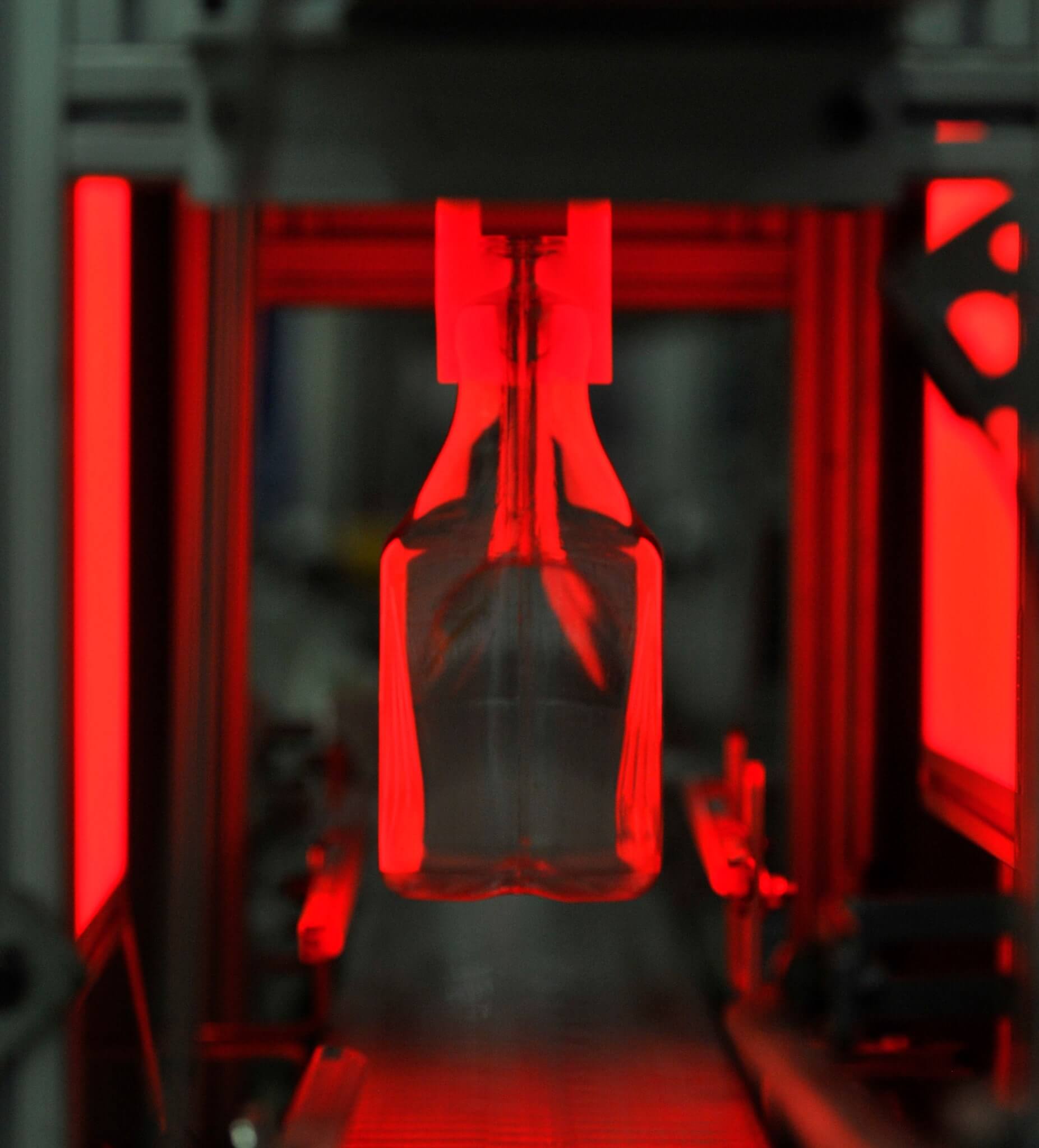

ePET

Plastipak merges PET and Extrusion Molding to create ePET packaging solutions.

Key Benefits

• Approved for food and beverage products

• ePET containers are clear, allowing for products to be fully visible to the consumer

• Unique shapes and sizes allow for options with handleware and wide-mouth openings

Extrusion Molding

With increased flexibility with new quick-change molds, Plastipak’s proprietary G.E.M. PAK Wheel provides an efficient platform to manufacture a wide variety of container shapes & sizes.

Key Benefits

• High output for reduced costs

• Increased consistency and bottle quality

• Single parison reduces variability

• Quick change mold systems

• Monolayer & multilayer extruded packages

• Designed for in-mold label capabilities

Wide Mouth Technology

Trimming technology provides a unique packaging shape. Available for fully recyclable PET and HDPE containers.

Key Benefits

• Plastipak offers PET and HDPE wide mouth containers with both round & non-round finishes

• Proprietary trimming technology enables unique packaging shapes

Lightweight Neck Finishes

A cost-effective technology for carbonated soft drinks and water applications. Lightweight performs and bottles reduce overall material consumption.

Highlights

Standard necks:

- CETIE GME 30.40

- Gravity

- Other regional variants

Lightweight neck finishes:

- 25/22 (1)

- 26/22 (1.96g)

Injection Molding

Globally manufacturing high volumes of clear and colored preforms. Recyclable preforms are made from a combination of new and recycled resin.